FeliciaLynn

Guest

The acrylic has been cut!!!

I went to TAP plastics after work and just got home with all the acrylic. It ended up costing me $55 for all the acrylic and cutting. Now I just have to glue it together and then silicone it into the tank. So excited to get going on this. I love DIY!

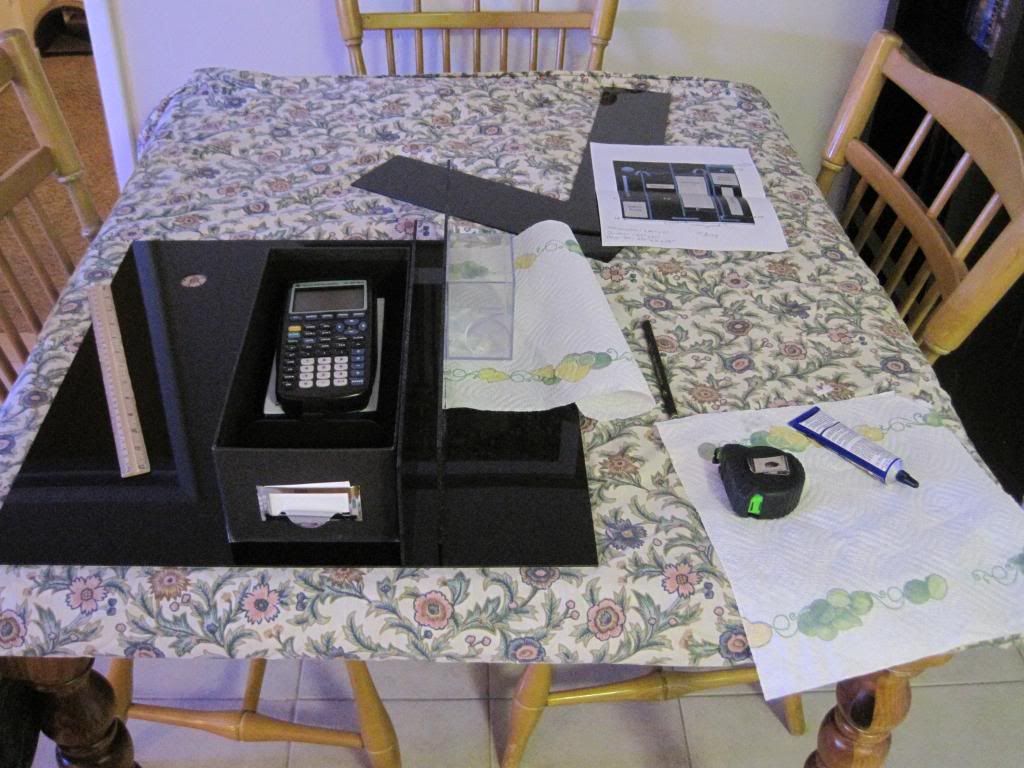

Pile of acrylic and the Weld-On (aquarium safe) to bond the acrylic pieces together. Silicone doesn't bond well to acrylic so to stick the pieces of acrylic together, I'll be using this stuff. Then to attach the acrylic to the glass is where the silicone comes in.

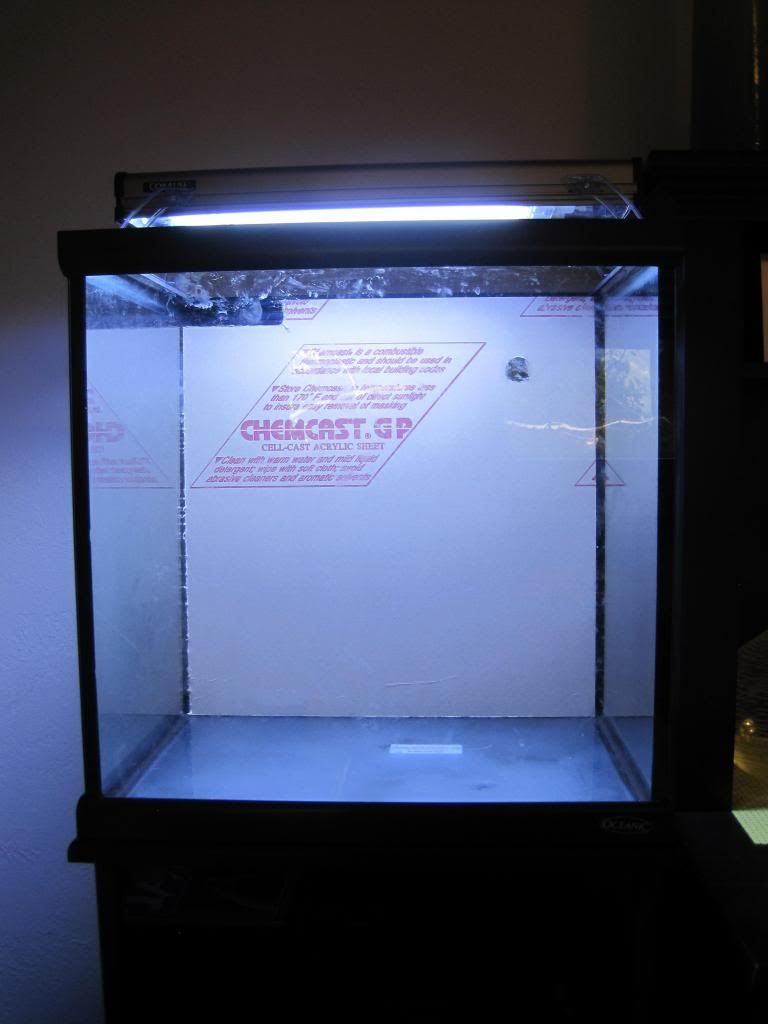

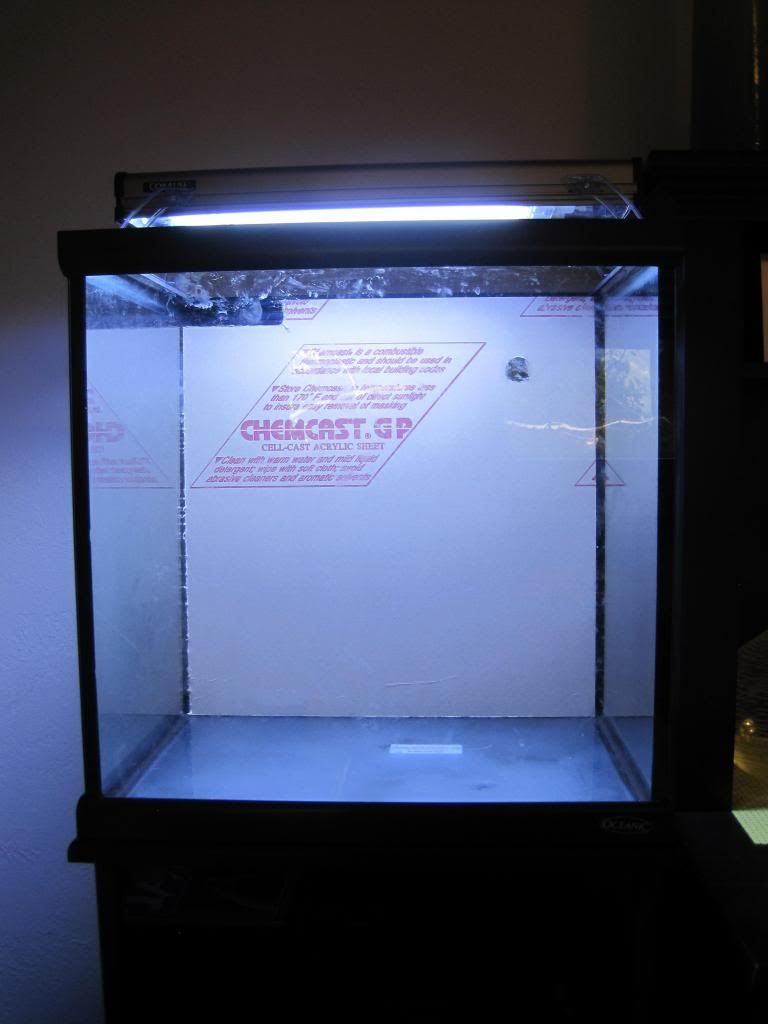

The partition fits nicely in the tank.

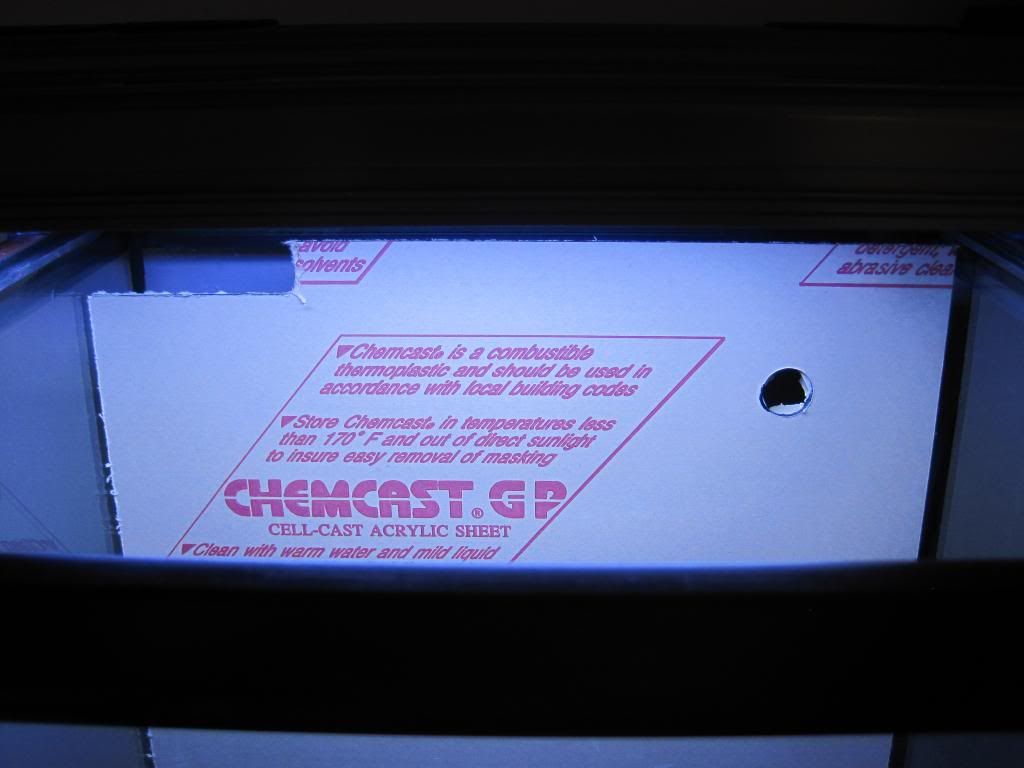

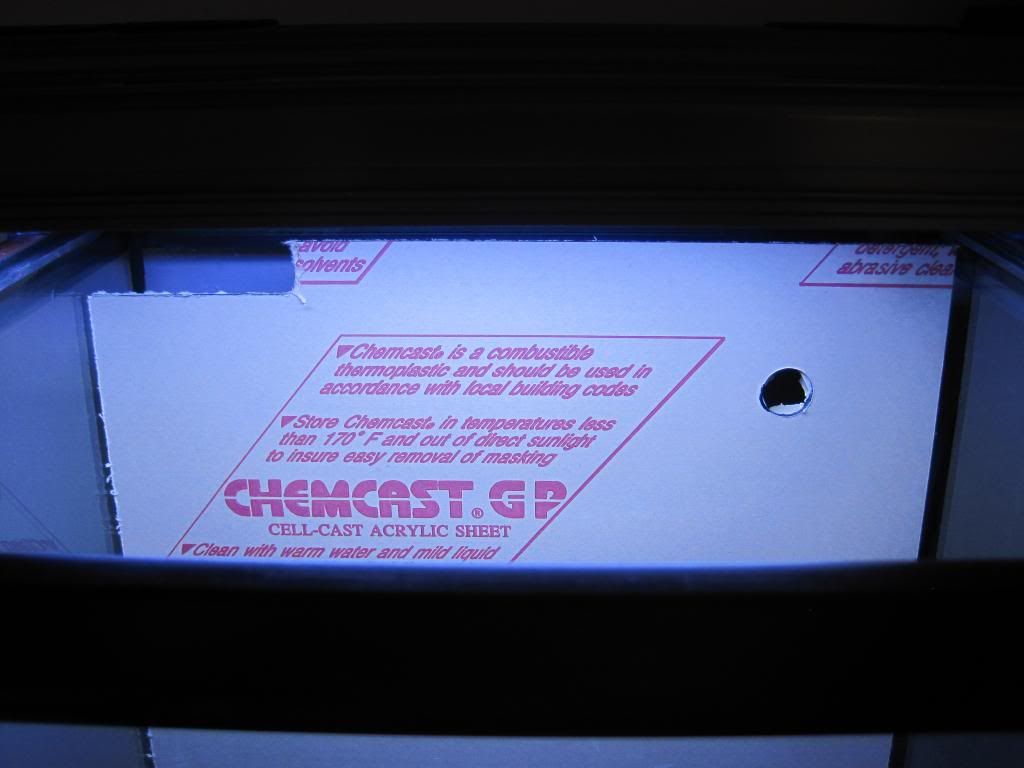

Overflow and hole for the return bulkhead.

Also, the new bulb and mounting legs came for the light fixture today. I took the entire light fixture apart and gave it a really good cleaning before attaching the legs and putting in the new bulb. You should have seen the balls of dust that had built up in the cooling fans. Its all clean now and looking nice. Also, with the new bulb in it, the light color looks great. I compared it to the main tank and it looks to be about the same color, which is awesome because I fine-tuned the white to blue balance on my main tank to exactly what I like. I can't change the balance on the power compact fixture, but its already just right! Yes!

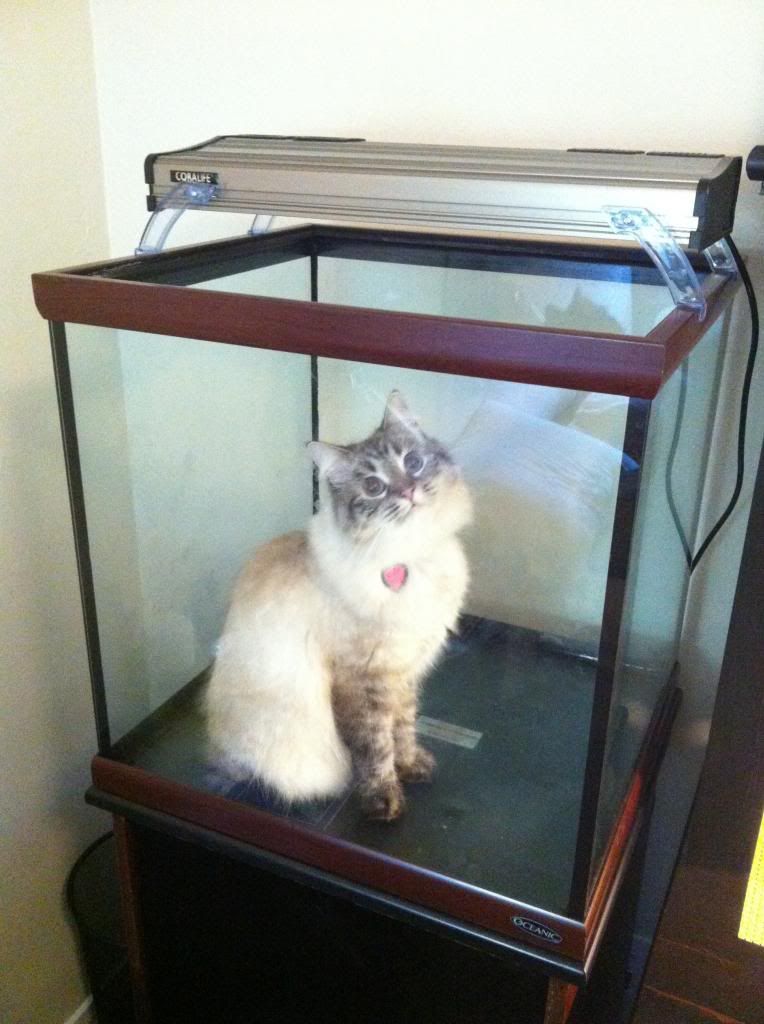

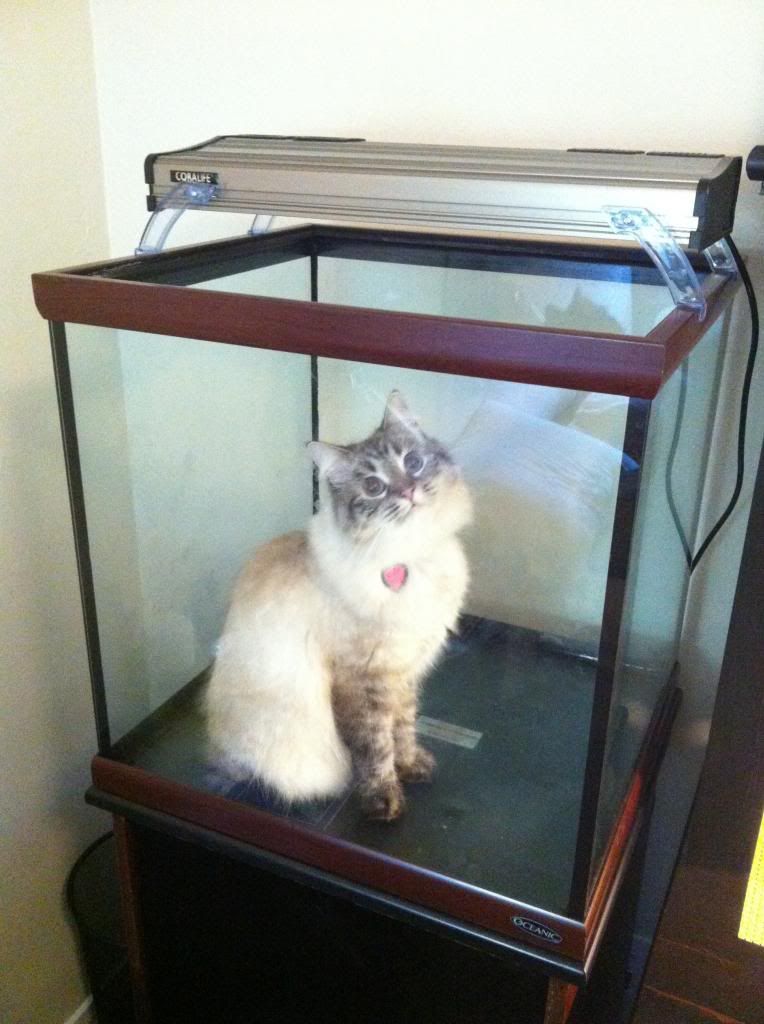

While I've been typing this post, I heard a loud thud in my bedroom. I got up and walked in there and Lily was in the new tank. I placed her in there for the photos I took earlier, so apparently now she's decided its fun to hang out in there. Here she is being cute.

"Well hello! You got this new toy for me right? So why do you seem annoyed that I'm in here?"

"See, its a fun new toy!"

I went to TAP plastics after work and just got home with all the acrylic. It ended up costing me $55 for all the acrylic and cutting. Now I just have to glue it together and then silicone it into the tank. So excited to get going on this. I love DIY!

Pile of acrylic and the Weld-On (aquarium safe) to bond the acrylic pieces together. Silicone doesn't bond well to acrylic so to stick the pieces of acrylic together, I'll be using this stuff. Then to attach the acrylic to the glass is where the silicone comes in.

The partition fits nicely in the tank.

Overflow and hole for the return bulkhead.

Also, the new bulb and mounting legs came for the light fixture today. I took the entire light fixture apart and gave it a really good cleaning before attaching the legs and putting in the new bulb. You should have seen the balls of dust that had built up in the cooling fans. Its all clean now and looking nice. Also, with the new bulb in it, the light color looks great. I compared it to the main tank and it looks to be about the same color, which is awesome because I fine-tuned the white to blue balance on my main tank to exactly what I like. I can't change the balance on the power compact fixture, but its already just right! Yes!

While I've been typing this post, I heard a loud thud in my bedroom. I got up and walked in there and Lily was in the new tank. I placed her in there for the photos I took earlier, so apparently now she's decided its fun to hang out in there. Here she is being cute.

"Well hello! You got this new toy for me right? So why do you seem annoyed that I'm in here?"

"See, its a fun new toy!"