You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a light fixture. Pipe bender

- Thread starter Sfork

- Start date

sfboarders

Guest

I used 3/4" EMT conduit. You can find it at the electrical section of HD/Lowes. PM Mario (xcaret). He has a tube bender and cutter.

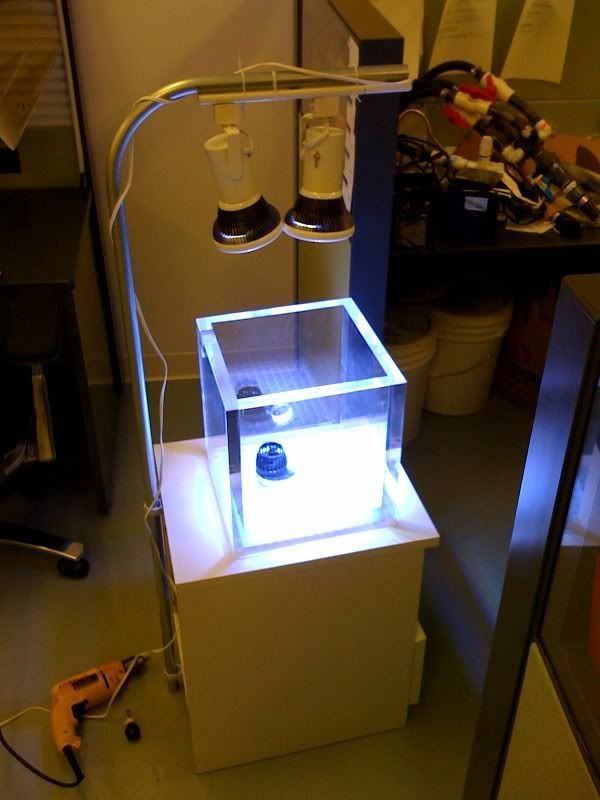

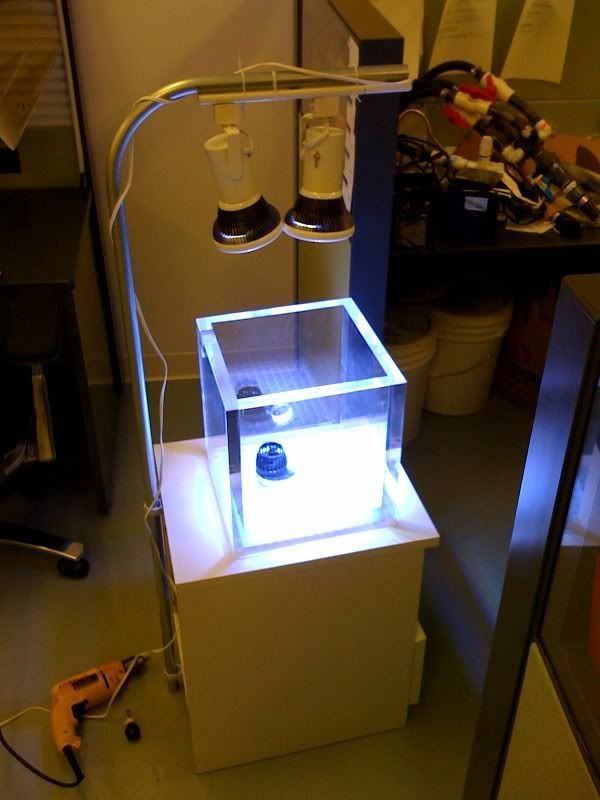

I made a light hanger from 3/4" pipe. It is hard as hell to bend "nice looking" if you've never done it before. IMO it looks way nicer than a 90 degree bend.

I coated mine with 3 layers of Rusto flat white. Looks good, no worries about saltwater getting on it. Best part is you can run all the wiring for the lamps through the pipe to conceal it better.

This photo is before I painted it, or ran the wire through the piping...but you get the idea. It is held in place with PVC pipe hanging brackets.

I coated mine with 3 layers of Rusto flat white. Looks good, no worries about saltwater getting on it. Best part is you can run all the wiring for the lamps through the pipe to conceal it better.

This photo is before I painted it, or ran the wire through the piping...but you get the idea. It is held in place with PVC pipe hanging brackets.

Mario can you help me out?  I'm heading into SF next Wednesday if you have the time!

I'm heading into SF next Wednesday if you have the time!

Thanks for the example Matt haha I didn't read your last sentence before looking at the picture and was like "wtf his picture looks nothing like what he described."

I have a plumbing question since I have everyone's attention. With the PVC do you guys just use non threaded with PVC cement to weld them or do you cut your own and thread them or is there a store somewhere with a good variation of different sizes? I went to HD and ACE today and they only had super long ones or small non threaded ones.

Thanks for the example Matt haha I didn't read your last sentence before looking at the picture and was like "wtf his picture looks nothing like what he described."

I have a plumbing question since I have everyone's attention. With the PVC do you guys just use non threaded with PVC cement to weld them or do you cut your own and thread them or is there a store somewhere with a good variation of different sizes? I went to HD and ACE today and they only had super long ones or small non threaded ones.

For PVC, use non-threaded and solvent-weld it, unless you have a specific piece that may need to be taken apart.

Tip : For the rare threaded PVC joints: Coat them with a touch of silicone, and do not over tighten.

It lubricates, stops leaks, and the does not really bond with PVC, so pipe still comes apart.

Tip : For the rare threaded PVC joints: Coat them with a touch of silicone, and do not over tighten.

It lubricates, stops leaks, and the does not really bond with PVC, so pipe still comes apart.

G

GreshamH

Guest

rygh said:For PVC, use non-threaded and solvent-weld it, unless you have a specific piece that may need to be taken apart.

Tip : For the rare threaded PVC joints: Coat them with a touch of silicone, and do not over tighten.

It lubricates, stops leaks, and the does not really bond with PVC, so pipe still comes apart.

and go light on using any teflon tape. Spears reports 9/10 of people use to many wraps of teflon which leads to failure. I use silicone and a little teflon (enough to go around 1.5 times)

No problem, just let me know and we will get to bend the pipe.

I've used heath shrink tubing and looks good, there are several colors available, hard to find in larger diameter and lengths, San Mateo Electronics is a good place for black and clear that I can think of.

BTW Matt, is the cube supposed to be bullet proof?

I've used heath shrink tubing and looks good, there are several colors available, hard to find in larger diameter and lengths, San Mateo Electronics is a good place for black and clear that I can think of.

BTW Matt, is the cube supposed to be bullet proof?

xcaret said:No problem, just let me know and we will get to bend the pipe.

I've used heath shrink tubing and looks good, there are several colors available, hard to find in larger diameter and lengths, San Mateo Electronics is a good place for black and clear that I can think of.

BTW Matt, is the cube supposed to be bullet proof?

Earthquake proof.