Tony, if it isn't too much of a PITA that would be greatly helpful. You are right something more 3d would be much more helpful as you are looking at actual space and depth etc.. For example, just looking at that hood in your sample picture I would say the luminarcs are way to close to the water and you are likely to have the "laser beam" effect I had when I tried it on my current hood.

If it is simple to use I would love to learn how to use it so I could throw some variables in it as it would give me a good idea of what to change now. My ultimate ultimate reason for kicking the tires is to determine what is most practical to meet my goals {having something that gives me room to work in the tank, optimize the lighting, and keep some semblance of style}. Doing something like this as well as getting other people's in progress opinions of best practices {what has worked best and what has failed miserably} will hopefully keep me from once again trying to massage something that wasn't designed properly in the first place.

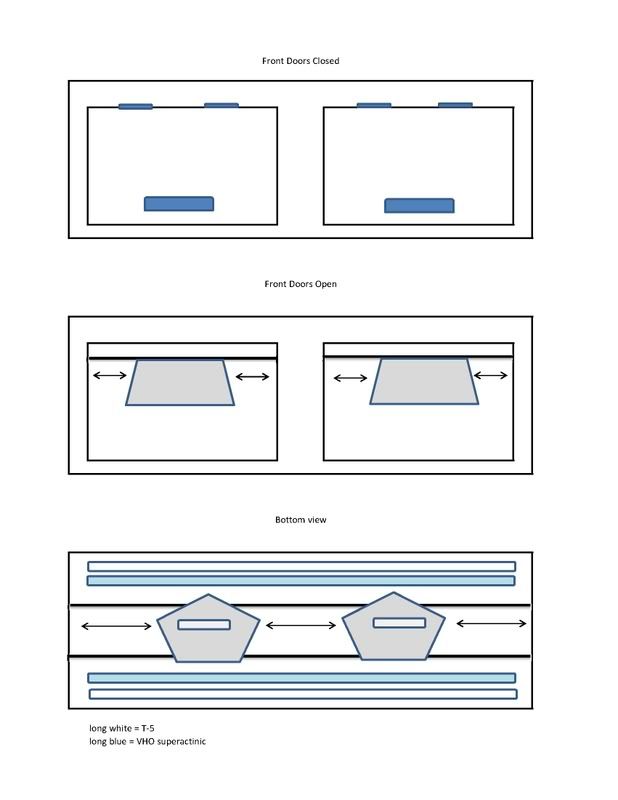

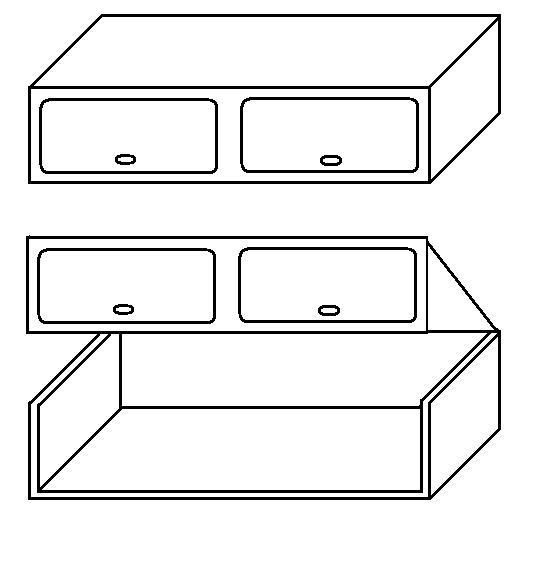

Not sold on the 2 door thing just have seen some that have looked nice and seemed to work well. Brian, when you say hinged lid to you mean from the top or the front (like the one in the diagram Tony listed)?