That's the Pro version. Maybe later. ;-)sfsuphysics said:My float switch is attached to a closed state-solenoid on the tap water side of things, mean it takes power to open the switch, when the float switch pops, it kills the power, solenoid shuts off water and stops flowing through the RO system. The fact that the solenoid is made of brass is irrelevant because its on the input side of things and no worse than copper pipes in your house, water doesn't enter the system until after the solenoid.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wow, really?! ANOTHER FLOOD! GRRR!!! Sooooo angry!

- Thread starter Vincerama2

- Start date

For a short time, maybe 2-3 months, yes.aqua-nut said:Mark,

Did your ASV work reliably when it was new?

It almost always fails now.

Tried cleaning it, shortening tubing, tightening things. No luck.

sfsuphysics

Supporting Member

Not exactly a bank breaking expense.xulio said:That's the Pro version. Maybe later. ;-)sfsuphysics said:My float switch is attached to a closed state-solenoid on the tap water side of things, mean it takes power to open the switch, when the float switch pops, it kills the power, solenoid shuts off water and stops flowing through the RO system. The fact that the solenoid is made of brass is irrelevant because its on the input side of things and no worse than copper pipes in your house, water doesn't enter the system until after the solenoid.

http://autotopoff.com/solenoid/

zeroinverse

Guest

rygh said:For a short time, maybe 2-3 months, yes.aqua-nut said:Mark,

Did your ASV work reliably when it was new?

It almost always fails now.

Tried cleaning it, shortening tubing, tightening things. No luck.

That's odd. I've had my setup for probably 9 months to a year.

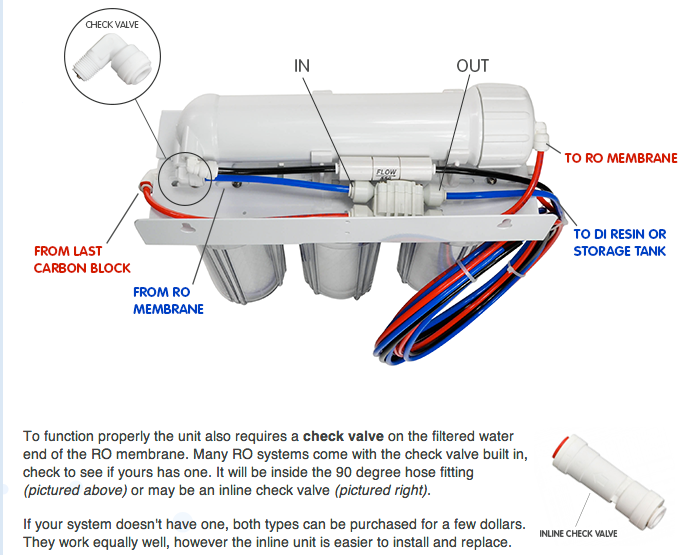

People seem to have had problems with not having a check valve installed causing "throttling" and/or failed/leaky float valves.

Nothing to indicate the ASO valve failure/leaking is the culprit.

http://www.reefcentral.com/forums/showthread.php?t=461299

http://www.reefcentral.com/forums/showthread.php?t=2137610

http://www.carolinafishtalk.com/forum/lighting-filtration-other-equipments-products/29934-ro-waste-water-wont-stop.html

http://www.reefcentral.com/forums/showthread.php?t=1344111

Maybe I missed the ASO valve failure articles. Would love to know since I want to make sure mine doesn't fail or leak like in your case. Would hate to waste water and/or have a flood in my garage.

zeroinverse

Guest

I wonder if those situations is because of "hard water" causing sediment clogs and/or too high water pressure causing the "ASO membrane" to get blown...

http://www.reefcentral.com/forums/showthread.php?t=1344111

BRS on their video suggest putting the ASO valve after the carbon blocks. Which probably help to remove any sediment/large particles that may break the ASO valve.

Looking forward to a good discussion to figure out how I should make my RODI setup more reliable.

http://www.reefcentral.com/forums/showthread.php?t=1344111

BRS on their video suggest putting the ASO valve after the carbon blocks. Which probably help to remove any sediment/large particles that may break the ASO valve.

Looking forward to a good discussion to figure out how I should make my RODI setup more reliable.

Vincerama2

Guest

My RO unit feeds the drinking water faucet too.

I have my RO unit. One line goes through a carbon filter then the drinking faucet. The other line (T'ed after the storage tank) goes through a DI cartridge and has a john guest valve on it, that's what the buckets fill from. Nothing automatic, and it takes 20 minutes for the storage tank to push out the water to the bucket.

Sounds like a nice idea to have a second holding tank that I could fill VIA valve, but also has a float valve to protect it from overflowing if I forget. Then put a tap on the bottom of that tank so I could fill a bucket quickly with it. Basically a non pressurized storage tank, that is manually filled. Hmmm...

If your ASV disconnects the tap supply, that would stop the works if you have a storage tank and drinking faucet.

V

I have my RO unit. One line goes through a carbon filter then the drinking faucet. The other line (T'ed after the storage tank) goes through a DI cartridge and has a john guest valve on it, that's what the buckets fill from. Nothing automatic, and it takes 20 minutes for the storage tank to push out the water to the bucket.

Sounds like a nice idea to have a second holding tank that I could fill VIA valve, but also has a float valve to protect it from overflowing if I forget. Then put a tap on the bottom of that tank so I could fill a bucket quickly with it. Basically a non pressurized storage tank, that is manually filled. Hmmm...

If your ASV disconnects the tap supply, that would stop the works if you have a storage tank and drinking faucet.

V

zeroinverse

Guest

V,

I am not sure how ASO valves work if they are trying to shutoff your "upstream" water which may have very little pressure differential.

ASO valves from what I read require that the "downstream" float valve stop pressure (between check valve and float valve) be at least 60% of your "upstream" pressure.

So technically sounds like it should work since the float valve will be "pushed up" to stop water flow. And since there is virtually NO pressure drop (since you have not RODI unit in the middle, just straight TUBING, you should be able to use the ASO valve. It's just a "redundant" valve in your case. Almost like you put two float valves in series.

================

Normally the concern for why an ASO may not work is if you can not achieve more than 60% pressure on the downstream side. That may happen if for some reason your RODI is extremely clogged and you get a huge pressure loss, or you did not put a check valve, etc, etc.

================

That is my understanding. Hopefully other people will chime in to make sure I did not make a mistake.

I am not sure how ASO valves work if they are trying to shutoff your "upstream" water which may have very little pressure differential.

ASO valves from what I read require that the "downstream" float valve stop pressure (between check valve and float valve) be at least 60% of your "upstream" pressure.

So technically sounds like it should work since the float valve will be "pushed up" to stop water flow. And since there is virtually NO pressure drop (since you have not RODI unit in the middle, just straight TUBING, you should be able to use the ASO valve. It's just a "redundant" valve in your case. Almost like you put two float valves in series.

================

Normally the concern for why an ASO may not work is if you can not achieve more than 60% pressure on the downstream side. That may happen if for some reason your RODI is extremely clogged and you get a huge pressure loss, or you did not put a check valve, etc, etc.

================

That is my understanding. Hopefully other people will chime in to make sure I did not make a mistake.

zeroinverse

Guest

On one of the replies, it seems like BRS RODI units has check valve integrated somewhere in the unit.

I looked at their site, and they definitely show one as part of the kit.zeroinverse said:On one of the replies, it seems like BRS RODI units has check valve integrated somewhere in the unit.

I cannot say for certain if I did not notice it or if it was never included in my kit.

But I did follow the video instructions pretty carefully at the time, so

my guess is that it has been added in the last few years.

zeroinverse

Guest

Rygh,

In one of the articles I linked, someone said BRS indicated there is a checkvalve build in or near the input/output of one of the units. Not sure if that is a recent addition to their setups or something else.

Anyways, just in case yours already has it.

In one of the articles I linked, someone said BRS indicated there is a checkvalve build in or near the input/output of one of the units. Not sure if that is a recent addition to their setups or something else.

Anyways, just in case yours already has it.

zeroinverse said:Rygh,

In one of the articles I linked, someone said BRS indicated there is a checkvalve build in or near the input/output of one of the units. Not sure if that is a recent addition to their setups or something else.

Anyways, just in case yours already has it.

Interesting. I will check this weekend.

With the kit now on the BRS site, it is clearly a separate piece.

Kensington Reefer

Supporting Member

Rule #1:

Never leave running water!

Water vessels fill faster when not watched!

The best floods are always buy employees.

"Why is there water all over the floor of the store? Where is the employee? Oh, he went to lunch!!!"

Ahhhhhhh

Sympathies to all who have flooded

Been there, cleaned that up!

Never leave running water!

Water vessels fill faster when not watched!

The best floods are always buy employees.

"Why is there water all over the floor of the store? Where is the employee? Oh, he went to lunch!!!"

Ahhhhhhh

Sympathies to all who have flooded

Been there, cleaned that up!

zeroinverse

Guest

My ASO does most of my "watching".

And worst case, it's in my garage.

And worst case, it's in my garage.

Vincerama2

Guest

The problem for me is taking a shortcut over my "best practices" method of 5 gallon fill up.

Procedure:

1) Put 5 g jug into sink

2) Turn on 20 minute timer (the kind that beeps, doesn't control anything)

3) Leave and come back when timer goes off

Shortcut:

0) Notice dishes in sink

1) Shove DI line into jug on floor

2) Turn on the water

3) Go play Skyrim for 3 hours

4) Clean up flood at 1AM

PS. Yes, I'm still playing Skyrim, I stopped for about a year then got addicted to it again since I never finished it when I first got it, and now my kids are less maintenance.

edit: Hey! I found an emoticon! apparently 0 ) is 0)

Procedure:

1) Put 5 g jug into sink

2) Turn on 20 minute timer (the kind that beeps, doesn't control anything)

3) Leave and come back when timer goes off

Shortcut:

0) Notice dishes in sink

1) Shove DI line into jug on floor

2) Turn on the water

3) Go play Skyrim for 3 hours

4) Clean up flood at 1AM

PS. Yes, I'm still playing Skyrim, I stopped for about a year then got addicted to it again since I never finished it when I first got it, and now my kids are less maintenance.

edit: Hey! I found an emoticon! apparently 0 ) is 0)

sfsuphysics said:Not exactly a bank breaking expense.xulio said:That's the Pro version. Maybe later. ;-)sfsuphysics said:My float switch is attached to a closed state-solenoid on the tap water side of things, mean it takes power to open the switch, when the float switch pops, it kills the power, solenoid shuts off water and stops flowing through the RO system. The fact that the solenoid is made of brass is irrelevant because its on the input side of things and no worse than copper pipes in your house, water doesn't enter the system until after the solenoid.

http://autotopoff.com/solenoid/

It depends. Are you somehow mechanically shutting-off power when a float valve pops-up? I would assume that a solenoid is to be connected to a controller that shuts-off power when a float switch sends it the appropriate signal.

sfsuphysics

Supporting Member

xulio said:sfsuphysics said:Not exactly a bank breaking expense.xulio said:That's the Pro version. Maybe later. ;-)sfsuphysics said:My float switch is attached to a closed state-solenoid on the tap water side of things, mean it takes power to open the switch, when the float switch pops, it kills the power, solenoid shuts off water and stops flowing through the RO system. The fact that the solenoid is made of brass is irrelevant because its on the input side of things and no worse than copper pipes in your house, water doesn't enter the system until after the solenoid.

http://autotopoff.com/solenoid/

It depends. Are you somehow mechanically shutting-off power when a float valve pops-up? I would assume that a solenoid is to be connected to a controller that shuts-off power when a float switch sends it the appropriate signal.

You could hook it to a controller, but since the solenoid is controlled by a 24v power supply (mine is, the one I linked to is an AC version) when the float switch pops all power stops. Even with the AC one you could hook up a relay like the sites water top off devices show, no controller needed at all.

zeroinverse

Guest

You can use electrical reed relay type switches to directly switch AC current. The only danger is you have a pair of thin 110vac wires near your tank. Seems dangerous to me.

Even with 24V DC, it is also a risk.

That is why using float switches with voltage (

Even with 24V DC, it is also a risk.

That is why using float switches with voltage (

Note that there is a nice 12V solenoid valve here:

https://www.sparkfun.com/products/10456

But it does pull 300mA, which is on the edge for some cheap float switches.

A relay would be best.

Curious : Why would 24V in the RODI fresh water tank be a safety issue?

https://www.sparkfun.com/products/10456

But it does pull 300mA, which is on the edge for some cheap float switches.

A relay would be best.

Curious : Why would 24V in the RODI fresh water tank be a safety issue?