bluprntguy

Guest

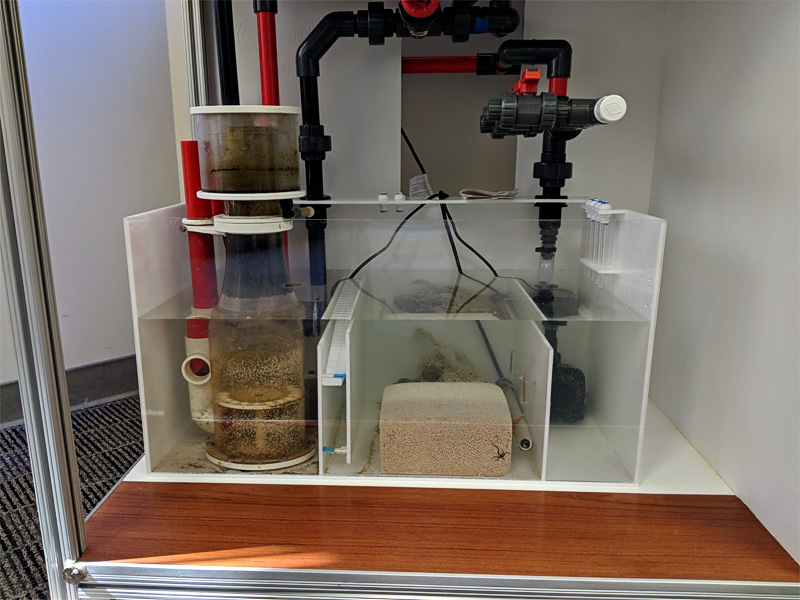

So, after some time off, I've decided to rebuild by nano.

I'm somewhat space constrained with my sump and need to have something custom built. Does anyone have some good recommendations?

I've already reached out to Modular Marine, but are there any other options that someone in the group knows about?

I'm somewhat space constrained with my sump and need to have something custom built. Does anyone have some good recommendations?

I've already reached out to Modular Marine, but are there any other options that someone in the group knows about?