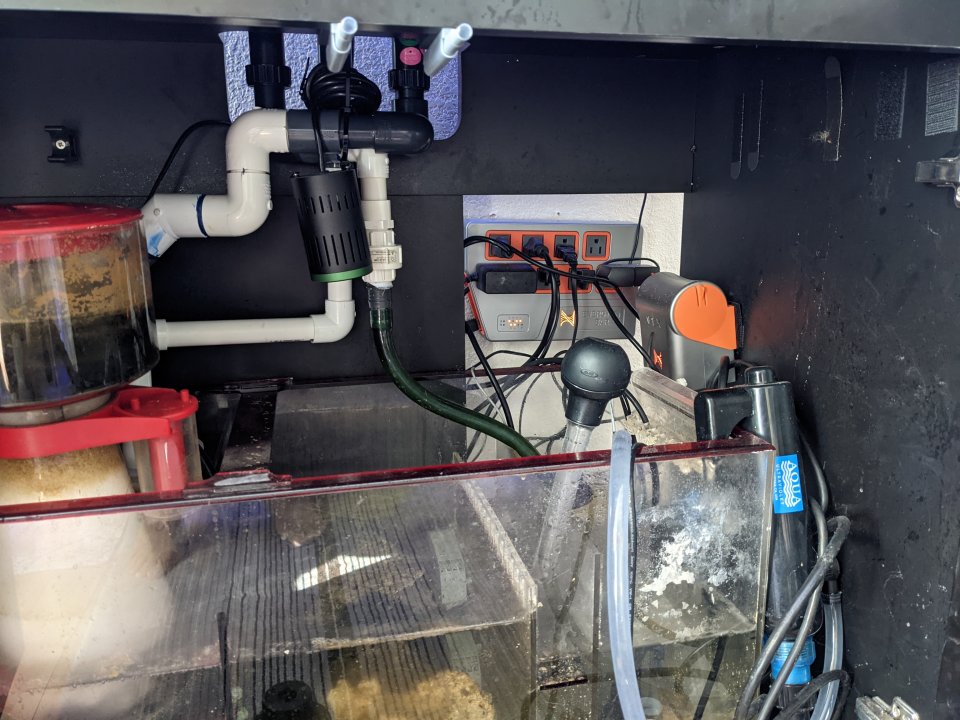

In an effort to make the DT look as clean as possible in our living room, I want to try and mount a shelf for my GHL doser and upcoming Trident inside my cabinet. I don't trust velcro straps to hold that much weight, and I'd rather not have several hundred dollars of equipment tumble into the sump, so does anyone have any ideas/has drilled the interior of these? Picture below (though I'll be moving the Apex base unit elsewhere so the entire right wall can be used for equipment):

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drilling/mounting things on the inside of a RSR 250 cabinet?

- Thread starter IOnceWasLegend

- Start date

I would mount a piece of nice looking plywood to the inside so you have real wood you can screw the shelf into. The MDF that most stands are won't take a screw, so you need real wood in there. You can go fancy like me and use all-thread drops with polycarbonate shelves, but I went a little overboard with that. The simple solution is plywood, cut to size, and mounted with lots of screws so the load is distributed. I would actually run the screws from the outside so you have the head of the screw sandwiching the MDF and the plywood. Get nice black oxide screws so they blend in, or putty over them and repaint. Then the plywood can take a couple screws and hold real loads. From there, I might use a 1x8 as my shelf, with a 2x4 underneath as support. Wood screws and an impact driver are your friends.

TLDR: MDF is bad...Real wood is good.

TLDR: MDF is bad...Real wood is good.

sfsuphysics

Supporting Member

Or you use the right tool for the right job. T-nuts are perfect for MDF and other particle/chip boards, simply drill a hole the size of it, pound it in from the back, and then you thread a bolt into it and not have to worry about the MDF blowing out on you.The MDF that most stands are won't take a screw, so you need real wood in there.

thesassyindian

Guest

If you want to cut brackets on a waterjet, let me know.

I recently repaired a (hand-me down) crib with support plates that I designed and waterjet from 1/8" 6061.

.

.

PS: That large hole was filled with wood gap filler.

I recently repaired a (hand-me down) crib with support plates that I designed and waterjet from 1/8" 6061.

PS: That large hole was filled with wood gap filler.

This sounds like a good idea; I'll consider this. Thanks!I would mount a piece of nice looking plywood to the inside so you have real wood you can screw the shelf into. The MDF that most stands are won't take a screw, so you need real wood in there. You can go fancy like me and use all-thread drops with polycarbonate shelves, but I went a little overboard with that. The simple solution is plywood, cut to size, and mounted with lots of screws so the load is distributed. I would actually run the screws from the outside so you have the head of the screw sandwiching the MDF and the plywood. Get nice black oxide screws so they blend in, or putty over them and repaint. Then the plywood can take a couple screws and hold real loads. From there, I might use a 1x8 as my shelf, with a 2x4 underneath as support. Wood screws and an impact driver are your friends.

TLDR: MDF is bad...Real wood is good.

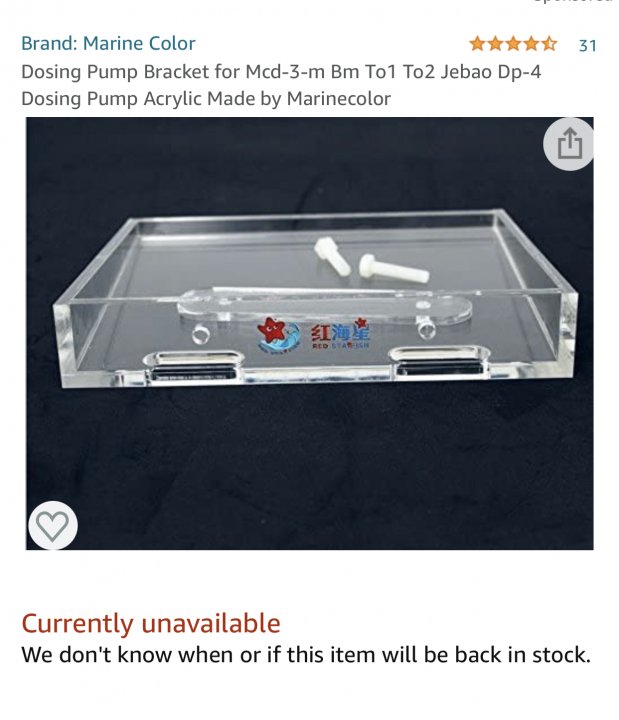

View attachment 33361Got one of these acrylic trays from Amazon, think it was $10-$15.

What is this mounted on? That's the perfect size since I'll be using a GHL doser as well.

thesassyindian

Guest

Cantilevered load bearing Acrylic gives me the heebie-jeebies :/View attachment 33361Got one of these acrylic trays from Amazon, think it was $10-$15.

Haha, me too depending on the load. In my journal, I did a shear calculation of the acrylic tank in my office to "prove" the overhang wasn't an issue. I can do another calculation if it helps on this piece, but I suspect the little acrylic shelf needs support underneath.Cantilevered load bearing Acrylic gives me the heebie-jeebies :/

This sounds like a good idea; I'll consider this. Thanks!

What is this mounted on? That's the perfect size since I'll be using a GHL doser as well.

Looks like the one I got is unavailable unfortunately, bet there are probably similar dosing pump holders.