Need an opinion. The rear corner of my new Reefer 500 stand has a gap between the top and the outer edge. It's only this one spot.

It's probably 1-3mm.

Is this concerning?

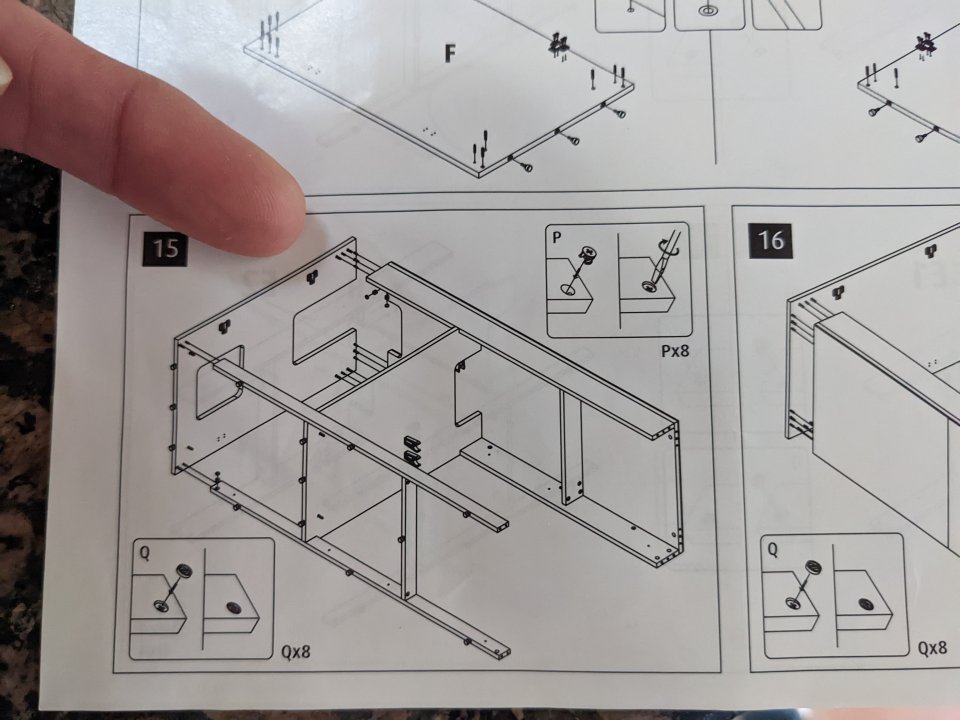

I've tried to fix it by ensuring I tightened all the screws in, and the cams, but it didn't change anything. Red Sea so far hasn't really given me guidance outside of trying to retighten things in ways I already did.

Visually I don't care, because it's the corner by the wall. I just want to ensure structural integrity isn't compromised.

The red sea stand in this corner has 4 bolts held in place with those rotating cams, and 2 plastic dowels:

My gut is this doesn't really matter, since it's not really changing the force directions, but...

It's probably 1-3mm.

Is this concerning?

I've tried to fix it by ensuring I tightened all the screws in, and the cams, but it didn't change anything. Red Sea so far hasn't really given me guidance outside of trying to retighten things in ways I already did.

Visually I don't care, because it's the corner by the wall. I just want to ensure structural integrity isn't compromised.

The red sea stand in this corner has 4 bolts held in place with those rotating cams, and 2 plastic dowels:

My gut is this doesn't really matter, since it's not really changing the force directions, but...