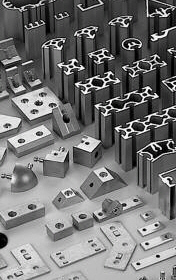

I'm researching the materials needed to use Tslot extrusions for a stand.

Tank is 48/30/20 and I'm using a 2000 lb load in the 80/20 deflection program.

Anyone know what is the max deflection I should aim for?

Want to span the whole 48" in the front but I need to know how big I need to go to achieve that safely.

Sent from my iPhone using Tapatalk

Tank is 48/30/20 and I'm using a 2000 lb load in the 80/20 deflection program.

Anyone know what is the max deflection I should aim for?

Want to span the whole 48" in the front but I need to know how big I need to go to achieve that safely.

Sent from my iPhone using Tapatalk