sfsuphysics

Supporting Member

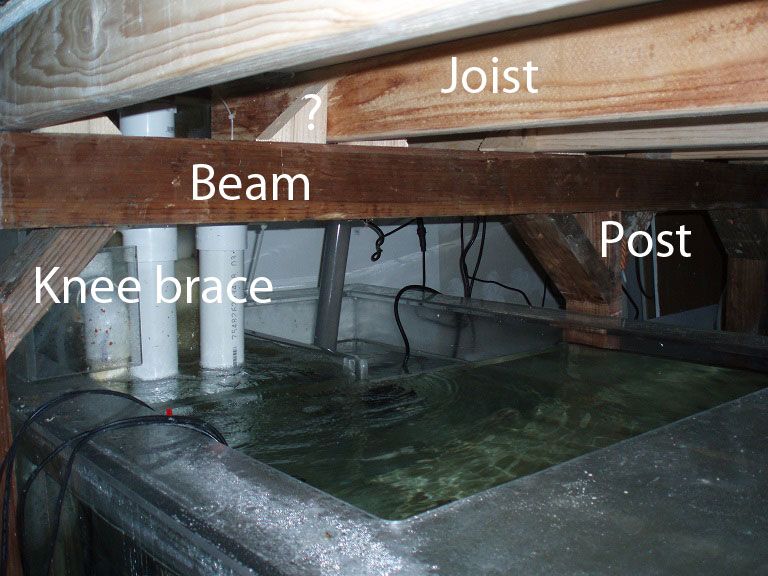

And overflow plumbing is done!

Put it through the ringer, and leak free.. .whew... I was worried about those screw connectors, due to the way I ran the piping and essentially connected both together there would be no further tightening going on. I did contemplate doing 4 separate pipes, however my mindset is that they're 2" pipes, the volume is there, and since there's 2 sets, the chances of one getting clogged is very small, doubly so considering the only thing that could get into the overflow would be small enough to easily get swept through the pipes. We'll see if that idea backfires, worst case is I'm out maybe $20 in PVC parts (2" fittings ain't cheap! Each elbow was $2 a piece!)

Unfortunately the side of the pipes does not allow me to really get too creative with herbie overflows, or a bean animal, etc.. I'll see how it works out with sound before I try to get creative in shutting it up. Downside is the tank came with like 4 - true union ball valves which are not cheap, the downside is that they have PVC welded to them in funky shapes that would make using them a bit impossible.

Oh well, display is about 80% filled, Sump is about 75% filled... ammonia is reading about 0.5ppm, so I'm getting close. Unfortunately I don't have any nitrite test kits to see where that's sitting, and don't feel like buying one that I'll use maybe 5 times at most. This whole cycle bit is hard to follow as it is, originally nothing but dry stuff, get a little ammonia spike, then I add more water, and more water and more water, basically gave it a 50% water change by doubling the water, then I add a bunch of live rock from my existing tank... oh well. My fish are staring at me from their holding pen wondering when they get to go play.

Ordered a bunch of stuff for lights, probably won't get those done until next week, but I might throw the fish in before then depending where ammonia is later this week.

Put it through the ringer, and leak free.. .whew... I was worried about those screw connectors, due to the way I ran the piping and essentially connected both together there would be no further tightening going on. I did contemplate doing 4 separate pipes, however my mindset is that they're 2" pipes, the volume is there, and since there's 2 sets, the chances of one getting clogged is very small, doubly so considering the only thing that could get into the overflow would be small enough to easily get swept through the pipes. We'll see if that idea backfires, worst case is I'm out maybe $20 in PVC parts (2" fittings ain't cheap! Each elbow was $2 a piece!)

Unfortunately the side of the pipes does not allow me to really get too creative with herbie overflows, or a bean animal, etc.. I'll see how it works out with sound before I try to get creative in shutting it up. Downside is the tank came with like 4 - true union ball valves which are not cheap, the downside is that they have PVC welded to them in funky shapes that would make using them a bit impossible.

Oh well, display is about 80% filled, Sump is about 75% filled... ammonia is reading about 0.5ppm, so I'm getting close. Unfortunately I don't have any nitrite test kits to see where that's sitting, and don't feel like buying one that I'll use maybe 5 times at most. This whole cycle bit is hard to follow as it is, originally nothing but dry stuff, get a little ammonia spike, then I add more water, and more water and more water, basically gave it a 50% water change by doubling the water, then I add a bunch of live rock from my existing tank... oh well. My fish are staring at me from their holding pen wondering when they get to go play.

Ordered a bunch of stuff for lights, probably won't get those done until next week, but I might throw the fish in before then depending where ammonia is later this week.